How To Choose The Right Storage Racking System For Your Warehouse

|

Aisle Selecting the right Storage Racking System Manufacturer In Delhi is crucial for optimizing warehouse operations. With a variety of options available, making the right choice can enhance efficiency, maximize space, and improve safety. Here are some essential considerations when choosing a storage racking system for your warehouse.

Conclusion Choosing the right storage racking system for your warehouse involves careful consideration of various factors, from space and inventory type to safety and cost. By partnering with a trusted storage racking system manufacturer in Delhi like Aisle, you can ensure that you find the ideal solution tailored to your specific needs. Investing the time to make an informed choice will lead to a more efficient and productive warehouse operation. Aisle is India's leading manufacturer of Storage Racking System Manufacturer In Delhi . You can contact them for further information regarding the Storage Racking System Manufacturer In Delhi. Visit us: https://www.aisleindia.com

|

karishma123

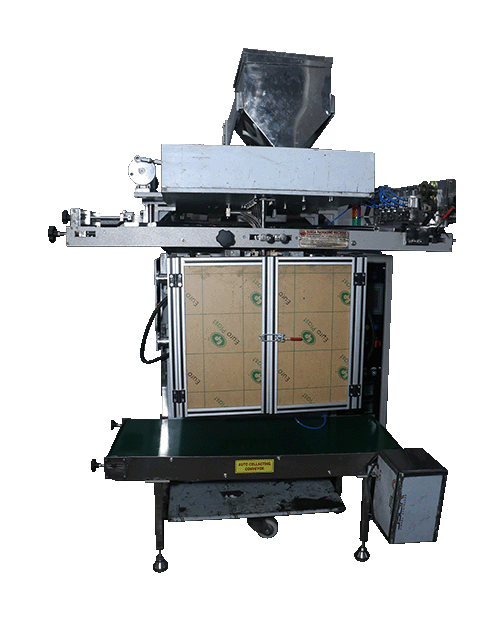

Durga packaging machine Choosing the right Sauce Pouch Packing Machine Manufacturer is crucial for optimizing your production line and ensuring product quality. Here’s a comprehensive guide to help you make the best decision for your business. Step 1: Assess Your Production Needs Before diving into machine specifications, evaluate your production needs: Volume: Determine how many pouches you need to pack per hour or day. High-volume operations require faster machines. Pouch Size: Identify the...

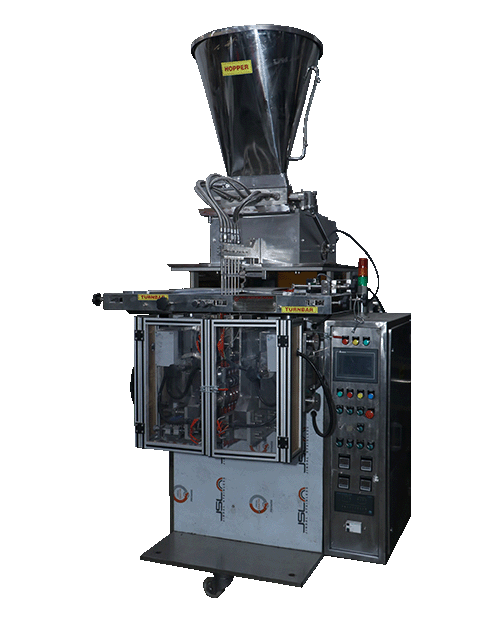

Durga packaging machine In the fast-paced world of manufacturing, efficient packaging is crucial, especially in the oil industry. Various types of Oil Packing Machine Manufacturer cater to different requirements and preferences. This blog aims to explore the different types of oil packing machines, highlighting their unique features and applications. Liquid Filling Machines Liquid filling machines are designed to dispense oil into containers with high accuracy. They are essential for ensuring...

Aisle In the ever-evolving world of warehousing and storage solutions, efficiency and organization are paramount. One of the most effective ways to enhance these aspects is by utilizing Fabric Storage Racks Manufacturer In Delhi. These innovative solutions are becoming increasingly popular among warehouse managers and logistics professionals. Let’s delve into the numerous benefits of using fabric storage racks in your warehouse. Space Optimization Fabric storage racks are designed to maximize...